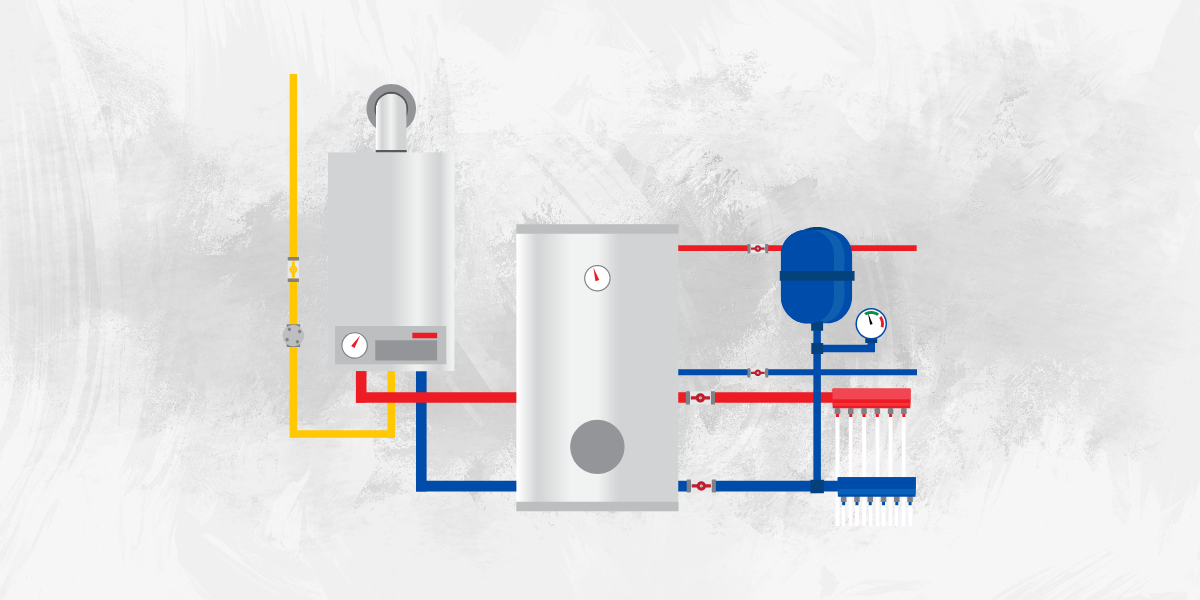

According to Wikipedia, a furnace is a tool used for heating. In American English and Canadian English, the term furnace on its own is normally used to explain family heating structures primarily based on a vital furnace known both as a boiler or a heater in British English and once in a while as a synonym for a kiln, a device used in the production of ceramics. In British English, the time period furnace is used exclusively to intend commercial furnaces.

To move lower back a bit in history, vital heating with a furnace is a concept this is centuries old. This idea was invented by the Romans and referred to as a hypocaust. It changed into a form of below-ground heating, the usage of a hearth in one corner of a basement with the exhaust vented through flues in the walls to chimneys. This form of heating may want to handiest be used in stone or brick homes. It was additionally very dangerous because of the possibility of a fireplace and suffocation.

Early furnaces burned wood. In the seventeenth century, coal started to replace wood as a primary fuel. Coal was used until the early 1940s, whilst fuel has become the number one fuel. In the Nineteen Seventies, electric-powered furnaces commenced updating fuel furnaces because of the power crisis. Wood and coal-burning furnaces required regular feeding to keep warmth within the domestic. From early morning to overdue at night time, normally three to 5 instances an afternoon, gas had to be put within the furnace. In addition, the waste from the ashes of burnt timber or coal had to be eliminated and disposed of. Today, the fuel furnace remains the most popular form of domestic heating system.

Raw substances – layout of unique fireplaces

Today, chrome steel is used inside the warmth exchangers for corrosion resistance. Aluminized metallic is used to assemble the body, blowers, and burners, and brass is used for valves, copper within the electric wiring, and fiberglass to insulate the cabinet. Today’s gasoline furnace includes a heat exchanger, secondary warmness exchanger (relying on performance score), air move blower, flue draft blower, fuel control valve, burners, a pilot mild or spark ignition, electronic manipulate circuitry and an outside thermostat. The cutting-edge furnace is exceedingly efficient-eighty-ninety%, permitting the best 10-20% of the heated air to get away up the chimney.

The production method nowadays.

• The number one warmness exchanger is formed from separate pieces of 409 chrome steel sheet. Each 1/2 is formed into form by way of a four-hundred-ton hydraulic press.

• The secondary heat exchanger is shaped from 29-four°C stainless steel tubing and fins. The fins are welded to the tubing to shape a radiator-type configuration.

• The number one warmth exchanger is crimped to the secondary warmness exchanger via a transition field. The flue draft blower is hooked up to the secondary warmth exchanger.

• The cupboard consists of two doors and the cupboard housing.

• The cupboard is installed around the furnace meeting and secured with screws and nuts.

• The doorways are set up on the front of the cupboard meeting. The finished assembly is boxed and organized for shipment.